About elkhorn products

Learn more about Elkhorn Products, our team, and what we're up to lately.

Elkhorn's all-star Team

HEATHER JONES

CEO

MBA candidate, software eng, tech PR, AI R&D director

5x award-winning author & US Army war vet

MBA candidate, software eng, tech PR, AI R&D director

5x award-winning author & US Army war vet

20 years in business, tech, & storytelling

Jeff Jones

Chief Researcher

Technician/inventor in high demand across the US

Responsible for systems worth $6B+

Technician/inventor in high demand across the US

Responsible for systems worth $6B+

4 patents & 48 years industry exp

and 6 OTHERS

with deep experience in engineering, grants, industrial contracts, construction, operations, & more

Elkhorn in the press

krambu selects elkhorn tech • july 2025

www.krambu.com

Krambu

We’re proud to announce a strategic partnership with Elkhorn Products, bringing their revolutionary Elkhorn 970 hydrovaporization cooling system to our future data center sites across the United States. This marks a major milestone in our journey to redefine what a data center can be: not just a utility, but a regenerative asset to the communities around it.

krambu data center tech demo • april 2025

KRAMBU PARTNERSHIP • FEB 2025

RESULTS

department of defense GRANT

DEPARTMENT OF THE NAVY SBIR PHASE I — USMC/MCSC

TYPE: FUNDING & AWARD

CONTRACT: M67854-25-C-6525

PURPOSE: To adapt compressor‑free, pure‑water (R‑718) HVAC for USMC's Amphibious Combat Vehicle.

TIMEFRAME: July 2025 - May 2026

CONTRACT: M67854-25-C-6525

PURPOSE: To adapt compressor‑free, pure‑water (R‑718) HVAC for USMC's Amphibious Combat Vehicle.

TIMEFRAME: July 2025 - May 2026

Essentials

- Scope: 55,000 BTU/hr target, 200–320 CFM fresh air, MIL‑STD‑1474 noise, SWaP optimization.

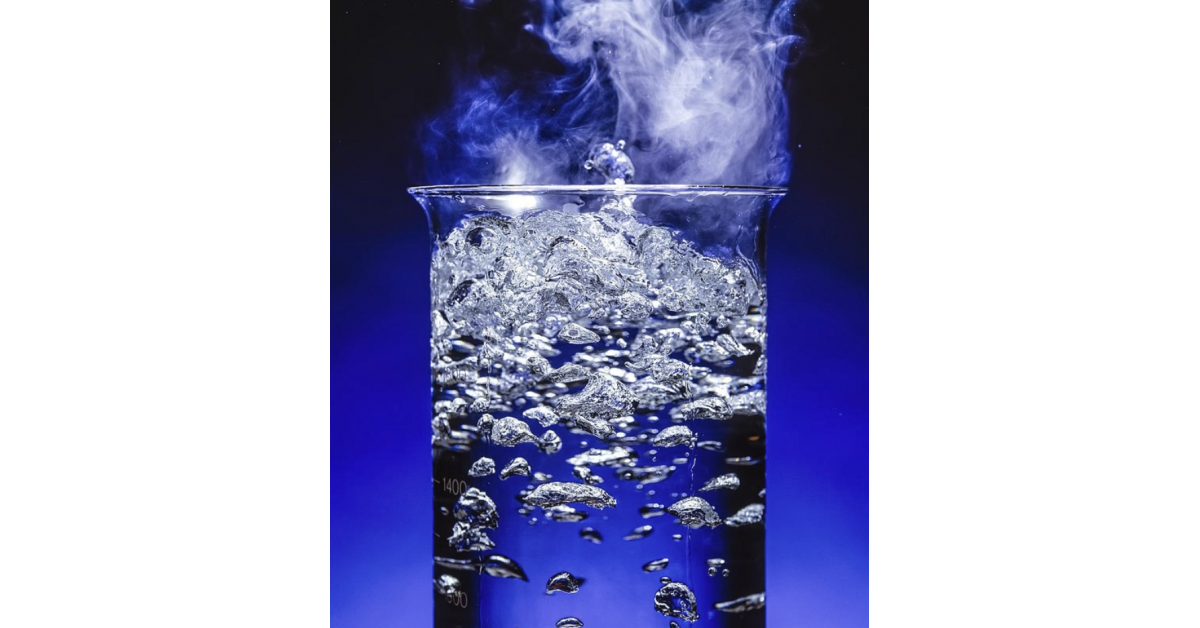

- Tech: Hydrovaporization™️ — no compressors, no oils, no HFCs; vacuum‑driven water cycle.

- Status: Phase I active; Phase II planned.

Why it matters

- Data centers: same architecture cut cooling energy ~50% in field demo; integrates with chilled‑water/immersion loops.

- Manufacturers/OEMs: simplified BOM (no compressor core); commodity stainless; drop‑in high stage for CO2 to stay subcritical.

- Industrial/commercial owners: lower energy and maintenance; quieter; 0 kg HFCs; retrofit‑friendly.

- Regulators & climate capital: aligns with AIM Act; path to decarbonize large-load cooling without synthetic refrigerants.

Funded by Department of the Navy SBIR Phase I Contract No. M67854-25-C-6525 (USMC/MCSC). The views expressed are those of Elkhorn Products and do not necessarily reflect the official policy or position of the Department of the Navy, the Department of Defense, or the U.S. Government. No endorsement is implied.

Photo by Seapower Magazine. Original article link.

krambu data center FIELD DEMO

NEWPORT, WA

TYPE: TECHNOLOGY DEMONSTRATION

PURPOSE: To test Hydrovaporization technology on a production crypto mining stack.

TIMEFRAME: 6-hour technology demonstration. April 2025

PURPOSE: To test Hydrovaporization technology on a production crypto mining stack.

TIMEFRAME: 6-hour technology demonstration. April 2025

Key results

- COP (system): ≈ 11.8

- PUE: 1.09 (down from 1.18 baseline)

- Cooling energy: ≈ 85 kW per MW IT vs ≈ 170 kW baseline

- Load: 3‑ton GPU heat removed with 1.93 kW drive power (2 hp)

- Refrigerant: 0 kg HFCs (water‑only, R‑718)

What it means

- Data centers: cut cooling energy and PUE without compressors; works with existing chilled‑water and immersion loops.

- Manufacturers/OEMs: fewer parts, no oils; easier manufacturing and service; CO2 cascade high‑stage option to keep subcritical.

- Industrial/commercial owners (hot factories, high‑rises, airports): 25–50% energy reduction, lower maintenance/noise; retrofit into existing water circuits.

- Regulators & climate capital: immediate HFC elimination; practical pathway to scale natural‑refrigerant cooling.

Learn more about KRAMBU: https://www.krambu.com/